Changing The Nozzle On A Creality Printer

The Creality series of printers allows you to change the printing nozzle, which gives you the flexibility to choose the nozzle that best suits your needs. In this guide, we will give you advice on how to choose the best nozzle size for your 3D printer. We’ll also show you how to change the nozzle on the 3D printer. This guide uses a Creality CR-10 to demonstrate the process, but the same steps apply to any Creality 3D printer, including the Ender 3, Ender 5, CR-10s Pro, and more.

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

How To Choose The Best Nozzle Size

Choose the nozzle size that best suits your 3D printing needs

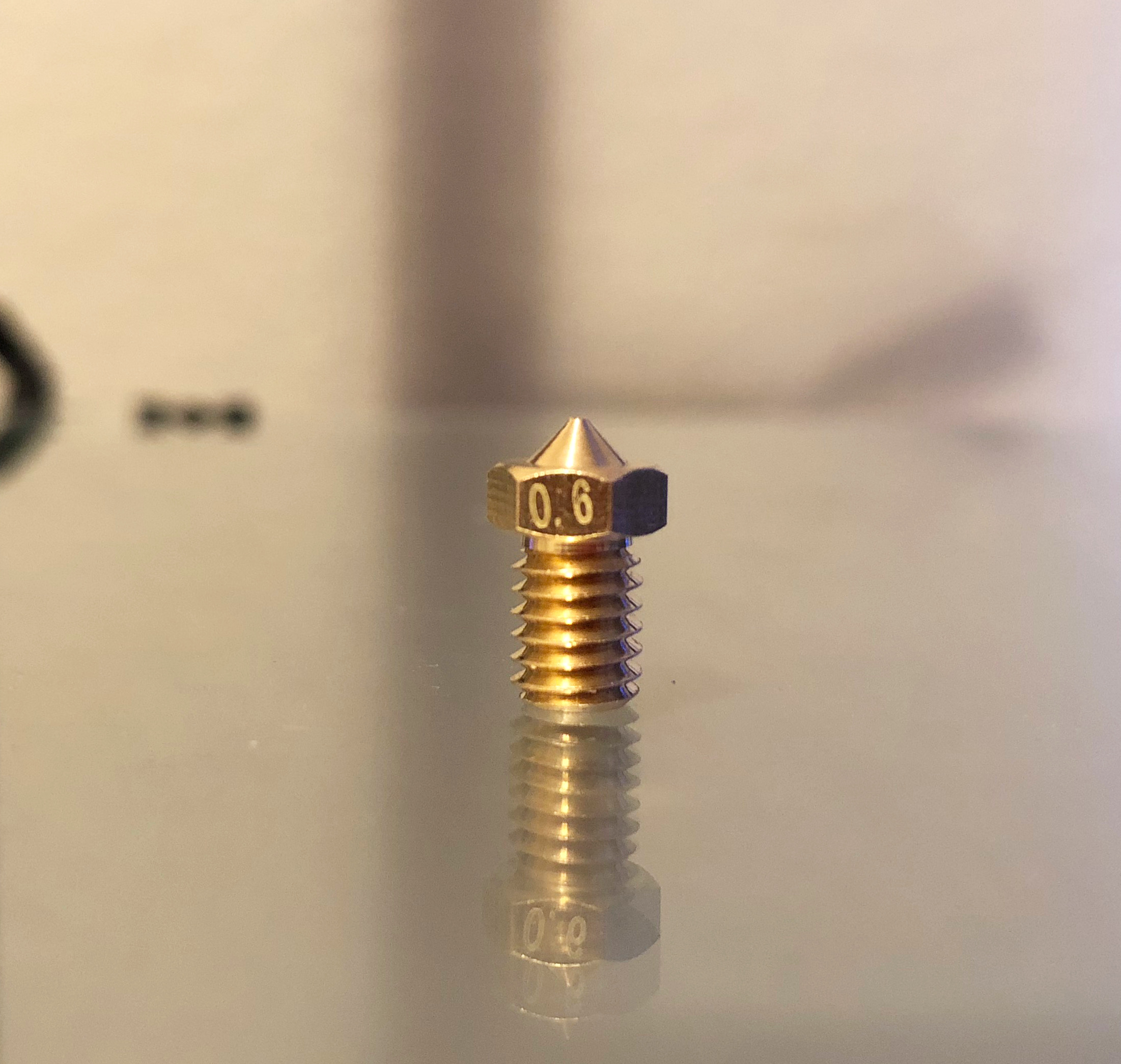

If you aren’t sure which one to use, get this variety pack of nozzles and start with the 0.6mm nozzle

Nozzle size is an important factor in 3D printing, and it is important to choose the correct nozzle size for your Creality printer. The best nozzle size for you is dependent on what types of models you want to print. There are several trade-offs to different nozzle sizes:

Larger nozzles:

allow you to use larger layer heights, which means that large models will take substantially less time to print

generally result in stronger prints

details and surface finish are more rough

Smaller nozzles:

excel at printing fine details

more desirable for prints that use support material because support material is generally easier to remove when a smaller nozzle is used

More precision is required for leveling the print bed

Common nozzle sizes range from 0.2mm up to 0.8mm The standard Creality CR-10 nozzle size is a balanced size of 0.4mm. While this is a good general nozzle size, you will find it to be frustrating if you are frequently printing larger models. Since we are often printing large models measuring 250mm or more, we prefer to use 0.6mm nozzles on most of our printers. We have found that a 0.5mm nozzle provides a good balance between the speed of a larger nozzle while still maintaining the ability to render details.

If you aren’t sure which nozzle size is best for you, we would recommend starting with a 0.5mm nozzle. If you’re confident that most of your prints will be large models that take full advantage of the build volume of the CR-10, the 0.8mm nozzle could be a potential upgrade.

Buy Your Nozzle

Recommended variety pack of nozzles: Amazon Link

The CR-10 uses a standard size 3D printing nozzle, which means that there a lot of purchasing options available. Our recommendation is this variety pack which will give you several nozzle sizes to experiment with.

Note that you can buy nozzles of other materials such as stainless steel. We don’t recommend these for general use because while they are more durable, they don’t conduct heat as well as brass. They should only be considered for abrasive filaments such as metalfill or woodfill.

By the way, it’s a good idea to have a spare nozzle or two. Nozzles wear out over time, which will eventually result in inconsistent printing quality. It’s also possible for the nozzle to become jammed with plastic or another obstruction. These issues don’t occur often, but when they do happen, it’s typically easiest to just replace the nozzle.

Remove The Old Nozzle

Heat the nozzle to 250C, then turn the heat off

Use a wrench to remove the nozzle

When you’re ready to change the nozzle, the first step is to remove the nozzle that is currently installed on your printer. To do this, you should first use the printer controller to heat the nozzle to 250C. This will loosen the nozzle so that it can be unscrewed later.

When the nozzle is heated to 240C, you should use the printer controller to set the nozzle heat to 0C to turn the heat off. Once you’ve turned the heat off, it’s time to remove the existing nozzle.

On the Creality CR-10 or Ender 3, the heater block is secured to the red heatsink assembly with two bolts, so you don’t have to worry about breaking the heater block when you unscrew the nozzle. However, some 3D printers such as the CR-10S Pro do not have these bolts. For these printers, you should use a wrench or pliers to hold the heater block as you unscrew the nozzle.

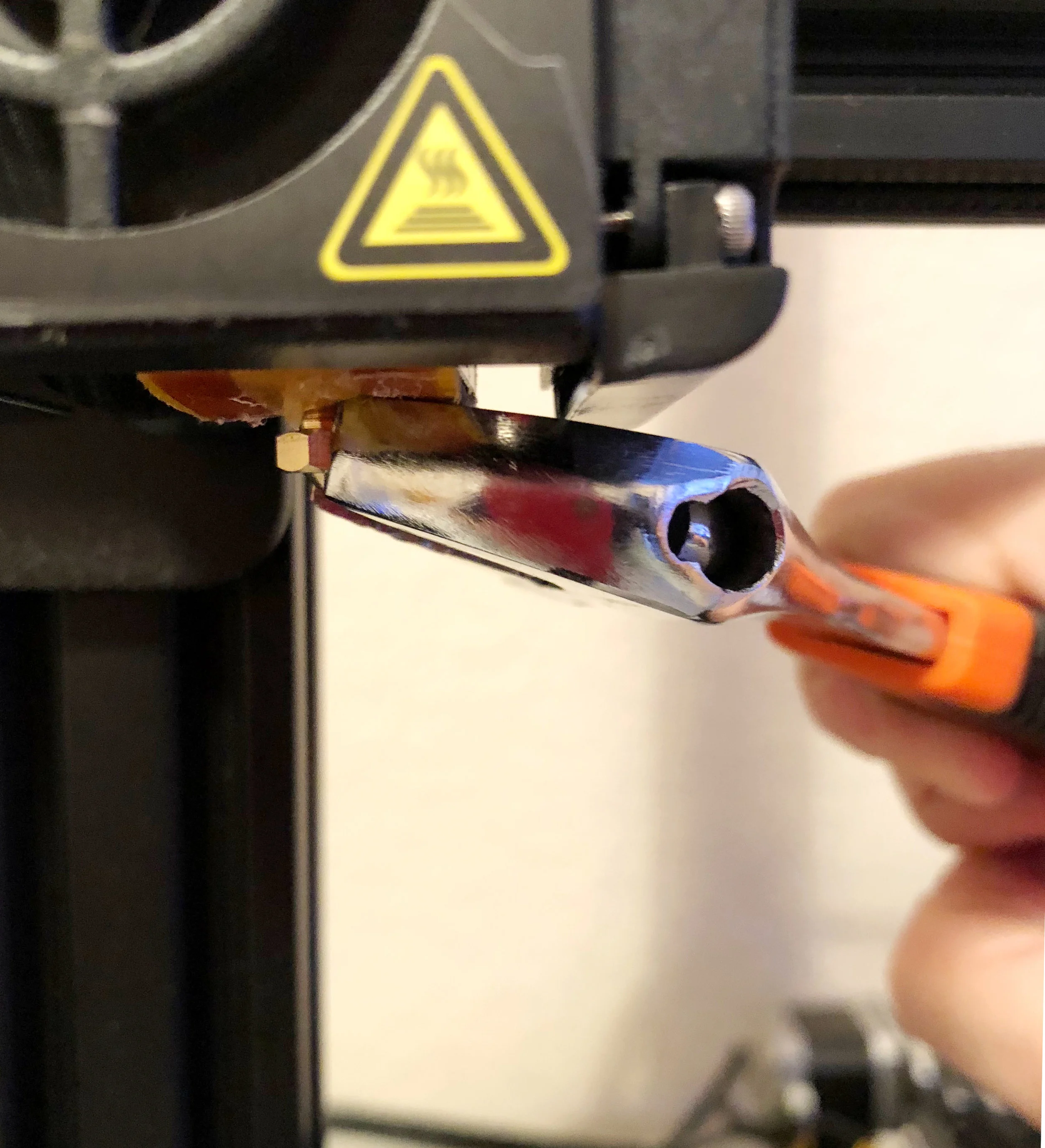

You can use the small wrench included with the printer or a crescent wrench to grip the nozzle and unscrew it. If you will be changing the nozzle often, we recommend these nozzle wrenches from Amazon which make it very easy to remove nozzles and install new ones. Be careful once the nozzle comes off of the heater block because it will still be very hot. We typically discard used nozzles since they are so cheap to replace, but if you want to reuse it, set the nozzle aside.

Newer CR-10s have two vertical bolts securing the heater block to the red heatsink. If your CR-10 has these bolts, there is no need to secure the heater block while loosening or tightening the nozzle.

You can use a wrench to unscrew the nozzle from the heater block.

We recommend these nozzle wrenches from Amazon which make this process very simple

Attaching The New Nozzle

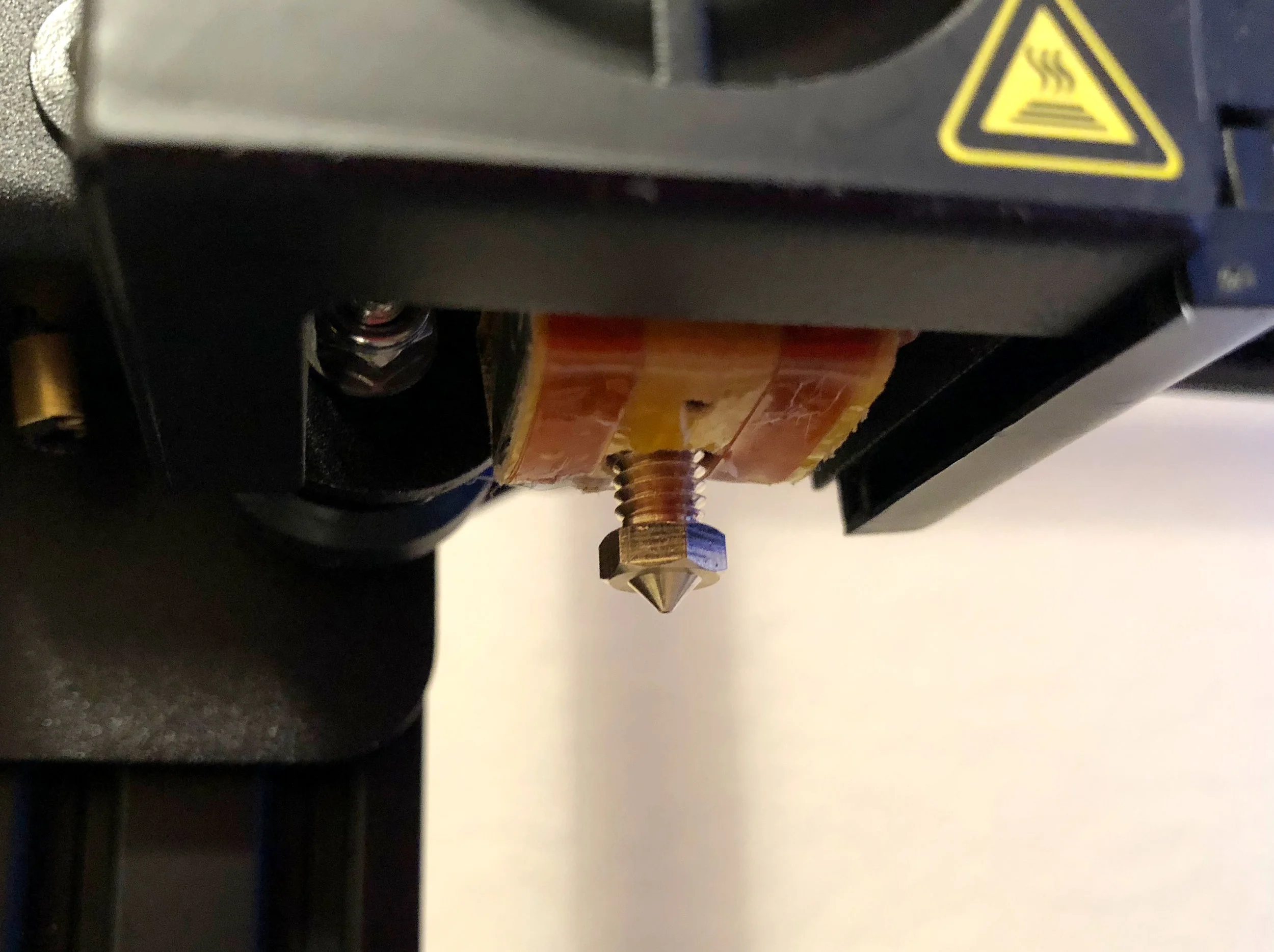

Screw the nozzle in by hand

Heat the nozzle to 250C, then turn the heat off

Use a wrench to tighten the nozzle

You can attach the new nozzle in the same way by screwing it into the heater block. You might be able to use the wrench to do this while the heater block is still hot, but we typically prefer to wait a few moments for the heater block to cool below 100C and then start screwing the nozzle in by hand.

Once the nozzle is partially screwed in, you should use the printer controller to heat the nozzle to 250C again. When the nozzle reaches 250C, turn off the heater and use a wrench to tighten the nozzle. You should tighten the nozzle until it is snug, but don’t use extreme force to tighten the nozzle.

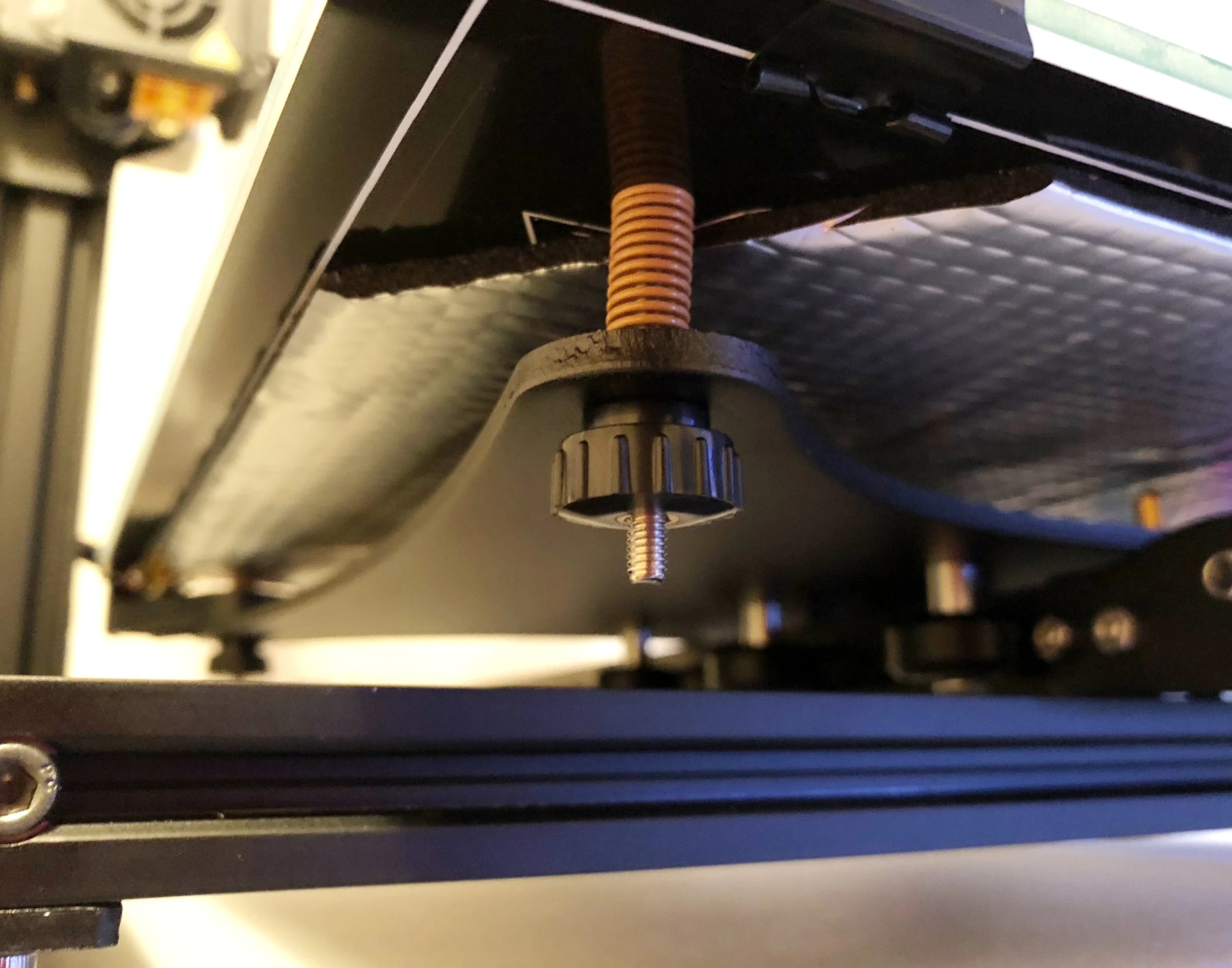

Re-Level The Print Bed

Re-level your print bed using our guide

When you change nozzles on the CR-10, you will affect how close the nozzle is to the print bed. Because of this, you will need to re-level the print bed after changing nozzles. Refer to our bed leveling guide for step-by-step instructions to level the print bed.

Success!

You've completed the nozzle changing process. Don't forget to change the nozzle size settings in your 3D model slicing software, and then go print something to test the new nozzle out!